Pasteurizer Enclosure

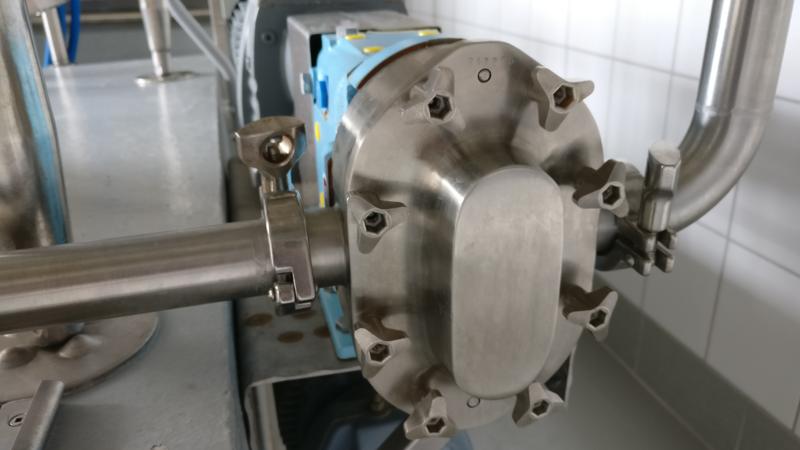

I built this enclosure for BoMé Cheese to control the pasteurization process. It features a variable frequency booster pump, heat recovery and differential pressure sensors.

The ΔP sensors are part of the legal requirements when running a booster pump. If the pressure on the raw side of the pasteurizer is higher than the pressure of pasteurized side, it is possible for pathogens to get through a pinhole in the regeneration (heat recovery) section of the plate heat exchanger.

To prevent this the pressure is measured and the booster pump is switched off if the difference is less than 3psi.

As is required, a total of 4 temperature sensors measure the output temperature of the pasteurizer. Two for the verification thermometer and two for the recorder/controller. If the temperatures dont match it shuts down.

The touch panel runs the whole show and reminds the user to check for common mistakes. It shows the input and output pipework that is being used and runs the cleaning programs as well.

The milk is heated with a hot water loop which is in turn heated with steam through a control valve. When the PID controller built into the recorder measures too little heat in the hot water loop it opens the control valve with an I/P (4-20mA to pressure) transducer.

This project was done together with Dairy Engineer, Horst Boehm, who designed the hardware and did the welding.